India's

Global Waste-Recycling and Resource-Recovery Company

An

ISO 9001:2008, ISO 14001:2004 & OSHAS 18001:2007 company

Hanjer Biotech Energies Pvt Ltd is an India based group with a proven track record of Solid Waste

Processing using Multi-Product Recycling and Waste Minimization (MPRWM). Waste management is the generation, prevention,

characterization, monitoring, treatment, handling, reuse and residual disposition

of solid wastes. There are various types of solid waste including municipal,

agricultural, and special. Disposing of

waste in an environmentally-friendly manner is crucial for a healthy and

hygienic environment. Hanjer

Biotech energies Pvt Ltd’s decade long experience in multiple locations with

varied climatic and weather conditions across India has perfected the process

and technology that can be implemented and work successfully anywhere in the

world. The principle of the process is to extract usable, commercially

viable end-products out of the MSW and create a processed remnant of less than

20% of the input volume, for the landfills. Hanjer Biotech Energies Pvt Ltd has

16 operating plants in India with total installed annual processing capacity of

2.95 million tones. 9 more projects with an additional 1.05 million ton

processing capacity are in implementation stage.

Hanjer Biotech Energies uses green technology to recycle Mixed Solid

Waste into valuable green products. These high quality end products are

suitable for commercial and industrial use, thus extending the value chain of

Hanjer Biotech Energies Pvt Ltd’s environment friendly processes and initiatives.

Hanjer Biotech energies Pvt Ltd produce Green Products with Green technologies.

They create Bio-organic Fertilizers, Recycled plastic, Green fuel and Residual

sand from waste.

Waste

to Compost from MSW

Bio-Organic fertilizer

is made by accelerated bio conversion process under controlled conditions using

remains of fruits, vegetables, food and by-products of agro process industry.

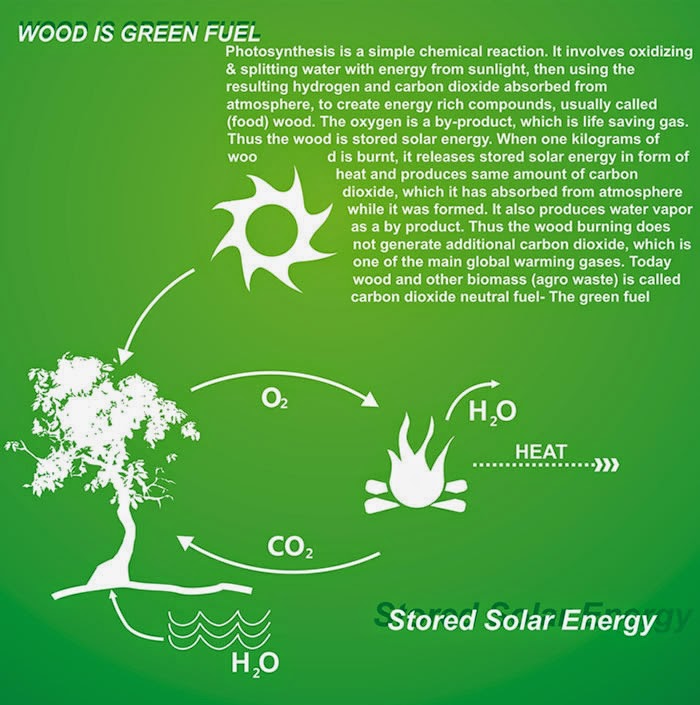

Green

fuel (RDF) from MSW

Dry municipal solid

waste is dried, crushed, screened and packed into brick form, used as

substitute to conventional fossil fuels in boilers.

Recycled

plastic from MSW

The plastic after being

segregated from mixed MSW is sorted into various grades using infra-red beams

and then converted to ingots/granules. It’s a completely dry process ensuring

no pollution or contamination.

Residual

sand from MSW

The processed remnant

material is further treated (in current operating plants) to extract any other

form of recyclables such as sand. It ensures that the material being sent to

the landfills is not more than 20%. The use of Hanjer

technology has positive impact on costs, environment and the community.

Save Cost. Save Environment. Save Earth

with Hanjer biotech Energies Pvt Ltd. Hanjer is building a 15 MW

RDF based power plant in Galla village, Surat district of Gujarat state in

India. The RDF green fuel is recovered out of Hanjer MSW processing facilities.

The power plant will be first of its kind in the country to run on 100% green

RDF. This Hanjer initiative conforms to the Renewable Energy Policy of the State

and Central Government. Green RDF is a clean and non-polluting fuel having very

good calorific value and hence there is no air pollution from operation of the

power plant.